Add to Cart

5500L Ultrasonic Washing Machine For Carbon Steel Pipe 32400W

Ultrasonic Cleaning Machine for Carbon Steel Pipe

After the carbon steel pipeline is used for a long time, the oil, dust, acid, alkali, and salt attached to the inner wall and standard surface of the pipeline are transformed into corrosive media under certain conditions, and chemically reacts with certain components in the carbon steel, resulting in chemical corrosion While rusty

When ultrasonic cleaning carbon steel pipes, the entire pipe needs to be immersed in the ultrasonic tank, and water and a certain proportion of chemical cleaning agent are added as the cleaning medium, so that the cleaning fluid can contact all corners of the inner wall of the pipe. Peel off the attached rust and dirt, so as to achieve the cleaning effect. There is no damage to the carbon steel pipes. The cleaning time is about 10~30 minutes. Multiple pipes can be cleaned at one time. The size of the ultrasonic cleaning tank is determined by the length of the pipe and the cleaning volume at one time.

Detailed Specification of this machine:

| 1 | Model | JP-1648ST | |

| 2 | Parameter | Function | Ultrasonic cleaning |

| Ultrasonic Frequency | 28/40kHz (other frequency can be customized) | ||

| Tank Material | SUS 304 (SUS 316 can be customized) | ||

| Thickness of tank | 3mm | ||

| Inner tank dimension | 3000*1500*1200mm | ||

| Tank Capacity | 5400L | ||

| Transducer | 648pcs | ||

| Ultrasonic Power | 32400W | ||

| Heating Power | 63000W | ||

| Time setting of Ultrasonic | 0~99 hours | ||

| Temperature setting | Room temperature ~ 95°C adjustable | ||

| Drain value | Available | ||

| Water inlet/outlet | Available | ||

| Generator | 18 sets | ||

| Generator power control | 1800W | ||

| Generator shelf | Available | ||

| Basket | Available | ||

| Basket load | 900KG | ||

| 3 | Packing | Overall size | 350*170*210cm |

| Packing size | 360*190*230cm | ||

| Packing detail | By wooden case(No logs, free of fumigation) | ||

| N.W/G.W | 1500KG/1600KG | ||

| 4 | Power supply | 380V 3 phase; 220V 3 pahse; 415V; 600V | |

| 5 | Warranty | 1 year warranty for spare parts, all life technical support | |

| 6 | Certificate | CE, RoHS; FCC, REACH | |

| 7 | Lead time | 20~30 working days after deposit | |

| 7 | Optional functions | Filtration cycle system | Available; capture dirty water, recycle clean water |

| Lifting system for basket | Available; take the basket up and down | ||

| Dunking system | Available; Speed up cleaning | ||

| Bubbling | Available; need to connect air compressor | ||

| Electrolysis | Available; For cleaning more complex structure mold | ||

| Cooling system | Available; To cool down inflammable and explosive | ||

| Constant temperature | Available; | ||

| Roller barrel | Available; for clean coins and big quantity parts | ||

| Anti-explosion electric box | Available; | ||

| Deionized(DI) water | Available | ||

| Double/Multi frequency | Available; 28/40/20/68/80/132KHz | ||

| Other funtions | Negotiate via email |

Other size and capacity for reference:

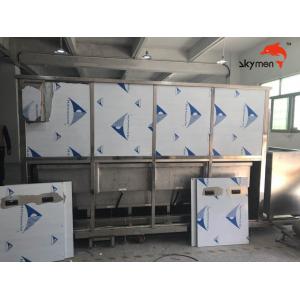

Product show:

Cleaning effect show:

Skymen Cleaning Equipment Shenzhen CO., Ltd.